Cable Winding Case Study

Cable Winding Case Study

Croylek recently undertook a cable winding project for a new customer that needed bulk cable conipacks to be rewound into useable reels.

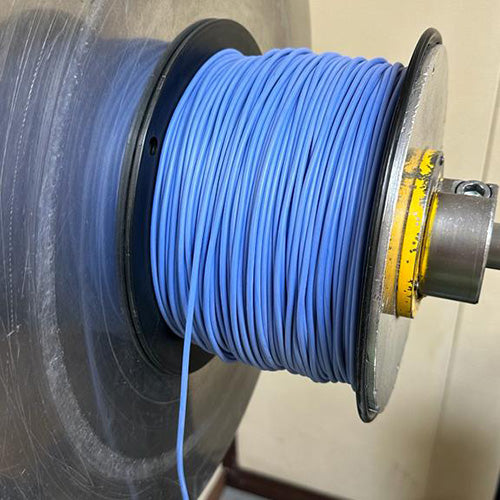

Our customer found themselves with 28,000 metres of cable packed in unmanageable drums.

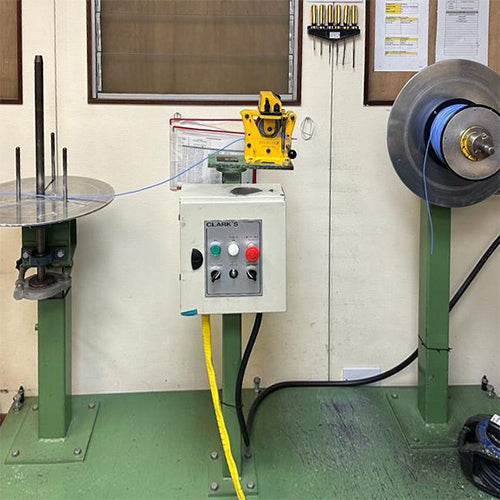

We wound down each drum onto small plastic reels with our bespoke small bore cable winding machine.

Running cable through the tru-meter counter allows for accurate measurement of each real.

In all, 112 smaller reels were created, each with 250m of carefully wound cable.

After winding, we shrink-wrapped & labelled the reels for easy shipping and storage.

Finally, we packed the reels in palletised boxes for safe transport back to the customer.

Could Croylek help you manage your cable in bulk? Drop us a line and we'll get back to you shortly.