- Sku: 64013914S

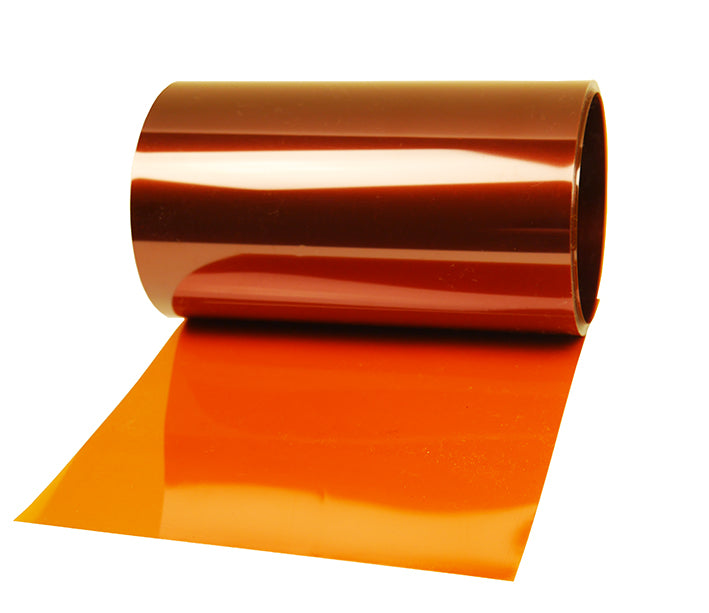

Croyfilm Polyimide Kapton® Film: 0.13mm X 914mm wide

Order by 2pm for next day UK delivery*

Size or colour not available? Contact us

International orders: shipping calculated after checkout

DESCRIPTION

This polyimide film is an excellent electrical insulation material, with outstanding thermal, mechanical, chemical and electrical properties. This versatile film has been used in applications where the environmental temperatures have been as low as -269 °C and as high is 400 °C and can be easily fabricated by a wide variety of techniques e.g. punching, die-cutting and thermal forming. This film can also be laminated, metalled or adhesive coated.

APPLICATIONS

- Electrical insulation

- Mechanical parts

- Electronic parts

- Insulation blankets

- Insulation tubing

- Fibre optics cable

- Pressure sensitive tape

- Etching

- Shims

- Automotive diaphragms sensors and manifolds

TECHNICAL INFO

|

Property |

Unit |

125microns |

Test Method |

|

|

Ultimate Tensile Strength |

at 23°C |

psi (MPa) |

33,500 (231) |

ASTM D-882-91, Method A |

|

at 200°C |

20,000 (139) |

|||

|

Ultimate Elongation |

at 23°C |

% |

82 |

ASTM D-882-91, Method A |

|

at 200°C |

83 |

|||

|

Tensile Modulus |

at 23°C |

psi (GPa) |

370,000 (2.5) |

ASTM D-882-91, Method A |

|

at 200°C |

290,000 (2.0) |

|||

|

Density |

g/cc |

1.42 |

ASTM D- 1505-90 |

|

|

MIT Folding Endurance |

cycles |

5,000 |

ASTM D-2176-89 |

|

|

Tear Strength-propagating (Elmendorf), N (lb./f) |

|

0.58 (0.02) |

ASTM D-1992-89 |

|

|

Tear Strength, Initial (Graves), N (lb/f) |

|

46.9 (1.6) |

ASTM D-1004-90 |

|

|

Yield Point at 3% |

at 23°C |

MPa (psi) |

69 (10,000) |

ASTM D-882-91 |

|

at 200°C |

41 (6,000) |

|||

|

Stress to produce 5% elongation |

at 23°C |

MPa (psi) |

90 (13,000) |

ASTM D-882-92 |

|

at 200°C |

61 (9,000) |

|||

|

Coefficient of friction, Kinetic (film to film) |

|

0.48 |

ASTM D-1894- 90 |

|

|

Coefficient of friction, static (film to film) |

|

0.63 |

ASTM D-1894-90 |

|

|

Refractive Index (sodium D line) |

|

1.70 |

ASTM D-542-90 |

|

|

Poisson’s Ratio |

|

0.34 |

Avg. three samples, Elongated at 5, 7,10% |

|

|

Low temperature flex life |

|

Pass |

IPC-TM-650, Method 2.6.18 |

|

|

Impact strength at 23°C |

N, cm ft.lb. |

78 0.58 |

DuPont Pneumatic Impact Test |

|

Thermal Properties

|

Thermal Property |

Typical Value |

Test Condition |

Test Method |

|

|

Melting Point |

None |

None |

ASTM E-794-85 (1989) |

|

|

Thermal Coefficient of Linear Expansion |

20 ppm/°C |

-14 to 38°C |

ASTM D-696-91 |

|

|

Coefficient of Thermal Conductivity W/m.K cal cm.sec.oC |

0.12

2.87 x 104 |

296 K

23°C |

ASTM F-433-77 (1987)

|

|

|

Specific Heat, J/g. K (cal/g. °C) |

1.09 (0.261) |

|

Differential calorimetry |

|

|

Heat Seal-ability |

Not heat sealable |

|

|

|

|

Solder Float |

Pass |

|

IPC-TM-650 Method 2.4.13A |

|

|

Smoke generation |

Dm = <1 |

NBS smoke chamber |

NFPA-258 |

|

|

Shrinkage, % |

30 mins at 150°C |

0.17 |

|

IPC-TM-650 Method 2.2.4A; ASTM D-5214-91 |

|

120 mins at 200°C |

1.25 |

|||

|

Limiting oxygen index - % |

37-45 |

|

ASTM D-2863-87 |

|

|

Glass Transition Temperature (Tg) |

A second order transition occurs in Kapton® between 360°C and 410°C and is assumed to be the glass transition temperature. Different measurements techniques produce different results within the above temperature range. |

|||

125 microns - Typical Electrical Properties at 23°C, 50% RH

|

Property Film Gage |

Typical Value |

Test Condition |

Test Method |

|

Dielectric Strength |

V/m kV/mm – 154 |

60Hz ¼ in electrodes 500 V/sec rise |

ASTM D-149-91 |

|

Dielectric Constant |

3.5 |

1kHz |

ASTM D-150-92 |

|

Dissipation Factor |

0.0026 |

1kHz |

ASTM D-150-92 |

|

Volume Resistivity |

1x1017 |

|

ASTM D-257-91 |

FEATURES AND BENEFITS

- Outstanding thermal, mechanical, chemical and electrical properties

- Excellent temperature range

- Easily fabricated by a wide range of techniques

- Flexible

- Radiation resistance

- Flame retardant

MATERIAL DATA

| Product Code | 6401 |

| Material | Polyimide Film |

| Standard Colour | Natural (amber) |

| Total Thickness – μ | 125 |

| Operating Temperature – °C | -269 – 400 |

| Elongation at Break – % | See technical table |

| Dielectric Strength – Kv | See technical table |

| Tensile Strength – N/cm | See technical table |

| Relevant Specifications | Kapton® Polyimide meets ASTM D-5213 (type 1, item A) requirements |

PRICE MATRIX

| SIZE | PRICE |

| 0.13MM X 914MM | £44.10 |